What Are Plastic Jersey Barriers?

The Plastic Jersey barrier, also called the New Jersey wall, was developed in the 1950s. They were designed to minimize vehicle damage if bumped into and prevent vehicle crossovers that could result in head-on collisions.

Typically, plastic barriers are hollow structures made of polyethylene. Designed to be lightweight and portable, they gain additional strength and stability by filling them with water or sand once they are onsite.

The barriers can be used for regulating traffic on freeways and around construction zones. Available in various shapes, sizes, colors, and price ranges, plastic barriers are also very useful for crowd control and sidewalks.

In cities and on highways, plastic barriers are an essential tool to protect drivers and workers undertaking highway development and maintenance.

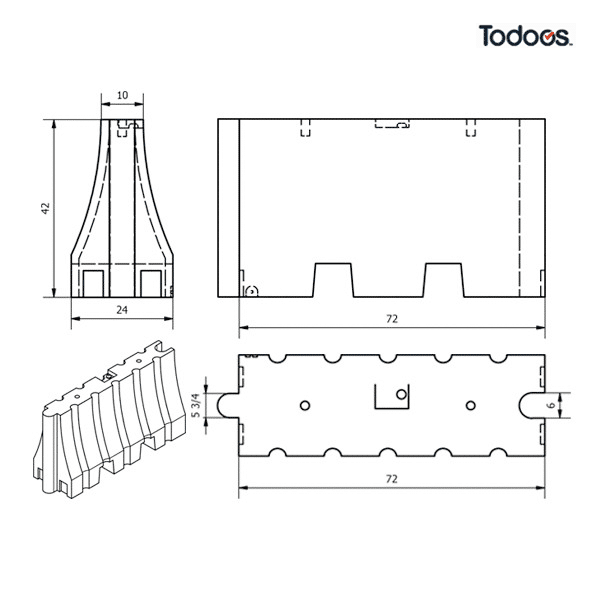

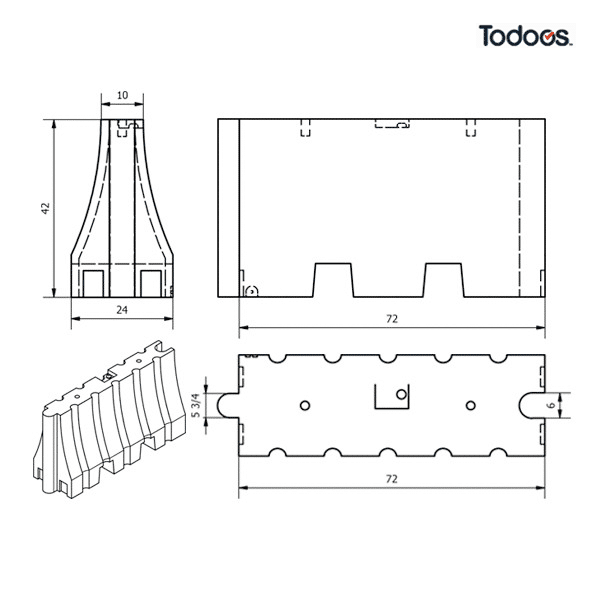

Each plastic jersey barrier is molded to a thickness of 8mm to ensure they do not burst upon filling. As long as they are maintained properly, they won’t crack or break due to their ability to resist the elements. Additionally, there are large drains to prevent water from piling up behind the barriers.

Make the roads safer with jersey barriers!

The highway barriers comply with the specifications in NCHRP (National Cooperative Highway Research Program) Report 350, “Recommended Procedures for the Safety Performance Evaluation of Highway Features”, allowing them to contain crashes at speeds up to 60 mph. The plastic highway barriers include metal reinforcements on both sides that help them remain stable even on impact.

Plastic barriers work well for highway safety, crowd control, and managing parking lots. They are lightweight, portable and more cost-effective than concrete barriers while maintaining a high level of safety.

We are happy to help in selecting the right product for you! Have a question about plastic jersey barriers? Call us to speak to a U.S. based Todoos Product Pro!

Highway safety experts agree that a solid barrier is the most important tool to prevent injury and death from potential crashes at highway repair projects.

While concrete barriers have been used for decades, the introduction of plastic jersey barriers changed the way things looked surprisingly fast.

Businesses prefer plastic barriers to concrete ones for two major reasons: lower cost and easier to move.

Plastic barriers are made from strong yet lightweight polyethylene, making them much more lightweight than traditional concrete barriers, while remaining effective to withstand collisions at speeds up to 60 mph.

The lighter design makes these barriers less expensive, less expensive to ship, and a perfect fit for highways, temporary project sites, and event venues.

Finally, transportation costs are also substantially lower due to the lighter design. These barriers are designed to be filled with water or sand only after they are placed in position. As plastic water-filled barriers do not even need to be anchored to the ground, they can be reused over and over again, thereby eliminating the need to purchase new barriers every so often.